INTRODUCTION

Waterborne polyurethanes (WPUs) are an important kind of environmentally friendly polymers widely used as coatings, adhesives, biomaterials, membranes etc.[1-3] Typically, WPUs are segmented polyurethanes containing hydrophilic components and/or ionic groups. Such structure features endow WPUs with many advantages, including good mechanical properties and water compatibility. Unlike conventional hydrophobic polyurethanes, WPUs can absorb water easily, and the resulted water containing materials are usually robust and flexible with mechanical properties comparable to most hydrogels.[4] On the other hand, WPUs have also been utilized as flexible substrates to fabricate stretchable electronic and optoelectronic devices, when ionic liquids (ILs), instead of water, are permeated into the WPUs networks.[5] For instance, skin-mimicking strain sensors with the ability to elicit electrical signals with the change of strain upon deformation have been reported using IL filled WPUs as the matrix.[6,7] In such applications, the mechanical integrity and resistance to failure of WPUs in various states, particularly in their swollen states, are of fundamental and technological importance. In this regard, exploring force probes that allow the study of mechanically induced polymer chain scission events with high sensitivity is desirable.

During the last decade, tremendous progress on polymer mechanochemistry has yielded a broad palette of mechanochromic mechanophores.[8-10] Covalent coupling these specific motifs with polymer backbones enables precise covalent transformations accompanied with perceptible optical signals by externally applied forces. Among various mechanochromic mechanophores, mechanochemiluminescent 1,2-dioxetane can provide a convenient and highly sensitive approach for visually identifying excess stress and/or strain in polymeric materials. The first mechanochemiluminescent polymer was discovered in 2012, by incorporating this chemiluminescent unit in a polymer main chain. Under mechanical force, the strained four-membered ring was opened, leading to two carbonyl (typically ketone) moieties, one of which was in an electronically excited state. When the excited ketone relaxed into the ground state, blue light (420 nm) emitted (Scheme 1a).[11] This mechanophore is specific for irreversible bond scission reactions that contribute to material degradation and unique in its auto-luminescent (without external light source) feature. Therefore, 1,2-dioxetane can serve as a molecular probe with much higher sensitivity than other optical force probes. So far, this mechanochemiluminescent transduction principle has been exploited to create many kinds of self-reporting polymers that provide unprecedented insight in the bond scission processes in segment polymers,[12-15] polyolefins,[16] multi-networks,[17,18] and filled polymer nanocomposites,[19-21] etc. The 1,2-dioxetane probe works well in bulk elastomers, however, its stress-reporting ability in wetting and polarized environment, e.g., when it is embedded in hydrophilic networks full-filled with large amount of polarized solvents, has not been reported. In these scenarios, 1,2-dioxetane usually suffered from significantly quenched fluorescence emission, due to the increased non-radiative relaxation of excited ketone intermediate in polar solvents.[22] Although further leaping the sensitivity of 1,2-dioxetane in terms of increased mechanoluminescence intensity and shifted emission color to longer wavelength was realized by energy transfer process,[11,15,23] most conventional fluorescent energy acceptors are not helpful in water or ionic environments.

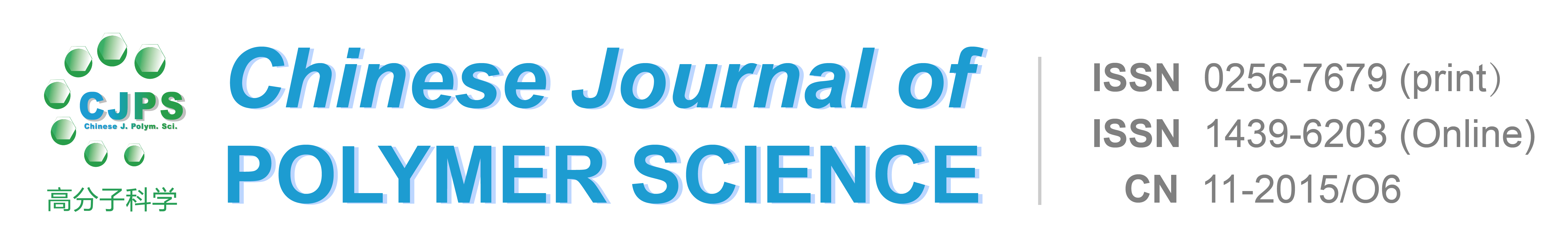

Unlike most hydrophobic fluorescent dyes, carbon dots (CDs) are promising fluorescent nanoparticles which possess many advantages including convenient synthesis, strong fluorescence, high photostability, low toxicity and good compatibility in water or ionic environments.[24-30] These factors inspired us to explore their application in mechanochemiluminescent WPUs. Herein, by well dispersing fluorescent CDs into the 1,2-dioxetane containing WPUs matrix, we prepared a new family of mechanochemiluminescent WPUs composites. Owing to the effective energy transfer process from mechanically activated 1,2-dioxetane to these fluorescent CDs, not only the bulk WPUs, but also their swollen films filled with large amount of polar solvents (water and IL) could emit intense mechanochemiluminescence. In this way, the details of stress/strain distribution and evolution within these WPU films in their different states could be visualized and monitored. Furthermore, a new kind of skin mimic strain sensor that can deliver both electrical and luminescent signals under mechanical activation was fabricated. The two types of outlet signals could be triggered at different strain ranges, and thus allowed for multimodal strain reporting responsive at an expanded strain range.

EXPERIMENTAL

General Considerations

Poly(ethylene glycol) (PEG, Mw=2000 g/mol, Comeo chemical reagent) was dried at 80 °C under vacuum for 8 h before use. Isophorone diisocyanate (IPDI) and dibutyltin dilaurate (DBTDL) were purchased from TCI. 2,2-Bis(hydroxymethyl)propionic acid (DMPA) was obtained from Innochem. Anhydrous N,N-dimethylacetamide (DMAc) was purchased from Energy Chemical. Citric acid and urea were purchased from Yuanli Chemical Company. o-Phenylenediamine (o-PDs) was purchased from Aladdin. 5,5’/7’-(2-Hydroxyethylenoxy) adamantylideneadamantane 1,2-dioxetane (Ad)[11] and 1-propyl-2,3-dimethylimidazolium bis(trifluoromethane sulfonyl)amide ionic liquid (IL) were prepared according to literature procedures.[31] 1H-NMR spectrum was recorded on a Bruker AVANCE III-400 NMR spectrometer under 25 °C using methanol-d4 as the solvent. FTIR spectra were carried out at room temperature in reflection mode on a Bruker Alpha spectrometer with a scan range of 400−4000 cm−1. The UV-Vis absorption and transmittance spectra were obtained on a PerkinElmer Lambda 750 spectrophotometer with standard procedure. Fluorescence spectra were recorded on a Hitachi F-7000 fluorescence spectrophotometer. Absolute quantum yields of CDs were recorded on Edinburgh instruments FLS-980 fluorescence spectrophotometer. X-ray photoelectron spectroscopy (XPS) characterizations were carried out with ESCALAB 250Xi (Thermo Scientific) spectrometer with a monochromatized Al Kα X-ray source (1486.7 eV). Raman spectrum was recorded on a DXR Microscope with 532 nm solid laser as excitation source. X-ray diffraction (XRD) profiles were obtained from DX-27mini X-Ray diffractometer with a Cu-target tube and a graphite monochromator. Transmission electron microscopy (TEM) observations were performed on a JEM-2100F microscope. The number average molecular weight (Mn) and polydispersity index (PDI) of WPU were determined by gel permeation chromatography (GPC) on a Hitachi L-2490 in DMF at 50 °C using polymethyl methacrylate as the standard. Differential scanning calorimetry (DSC) (TA DSC-Q20) measurements were performed under a nitrogen atmosphere at a heating and cooling rate of 10 °C/min. Dynamic mechanical analysis (DMA) measurements were carried out on dynamic mechanical analyzer TA Instrument Q800 in tensile mode at 0.2% strain. Temperature sweeps were run from −100 °C to 30 °C with a heating rate of 3 °C/min at 1 Hz. The tensile tests of IL containing WPU were performed using MTS Criterion Universal Test Systems of Model 44.

General Procedure for Preparation of WPU-CDs Films

400 mg of WPU-0 and CDs were dissolved in 10 mL of MeOH, and then poured into a Teflon mold (50 mm × 30 mm× 10 mm) to evaporate solvent and get a film. Films for rheological testing were cut into rectangles of 20 mm × 3.3 mm using a Zwick ZCP 020 manual cutting press equipped with a cutting blade of 3.2 mm width. The thickness of the films was 0.2±0.01 mm.

General Procedure for Preparation of Water Containing WPU-CDs Films

WPU-CDs films (20 mm × 3.3 mm × (0.2 ± 0.01) mm) were put in front of the outlet of a humidifier (JSQ107, purchased from Guangdong Chigo Air Conditioning Co., Ltd.) for 90 s, and the water contents (swelling ratios) of these films were calculated as 80%±10%. The water containing films were used for optomechanical tests immediately.

Preparation of WPU-CD2-1.2%-IL Films

400 mg of WPU-0, 5 mg of CD2 and 80 mg of IL were dissolved in 10 mL of MeOH, and then poured into a Teflon mold (50 mm × 30 mm × 10 mm) to evaporate solvent and get a film. Films for rheological testing were cut into rectangles of 20 mm × 3.3 mm using a Zwick ZCP 020 manual cutting press equipped with a cutting blade of 3.2 mm width. The thickness of the films was 0.2±0.01 mm.

RESULTS AND DISCUSSION

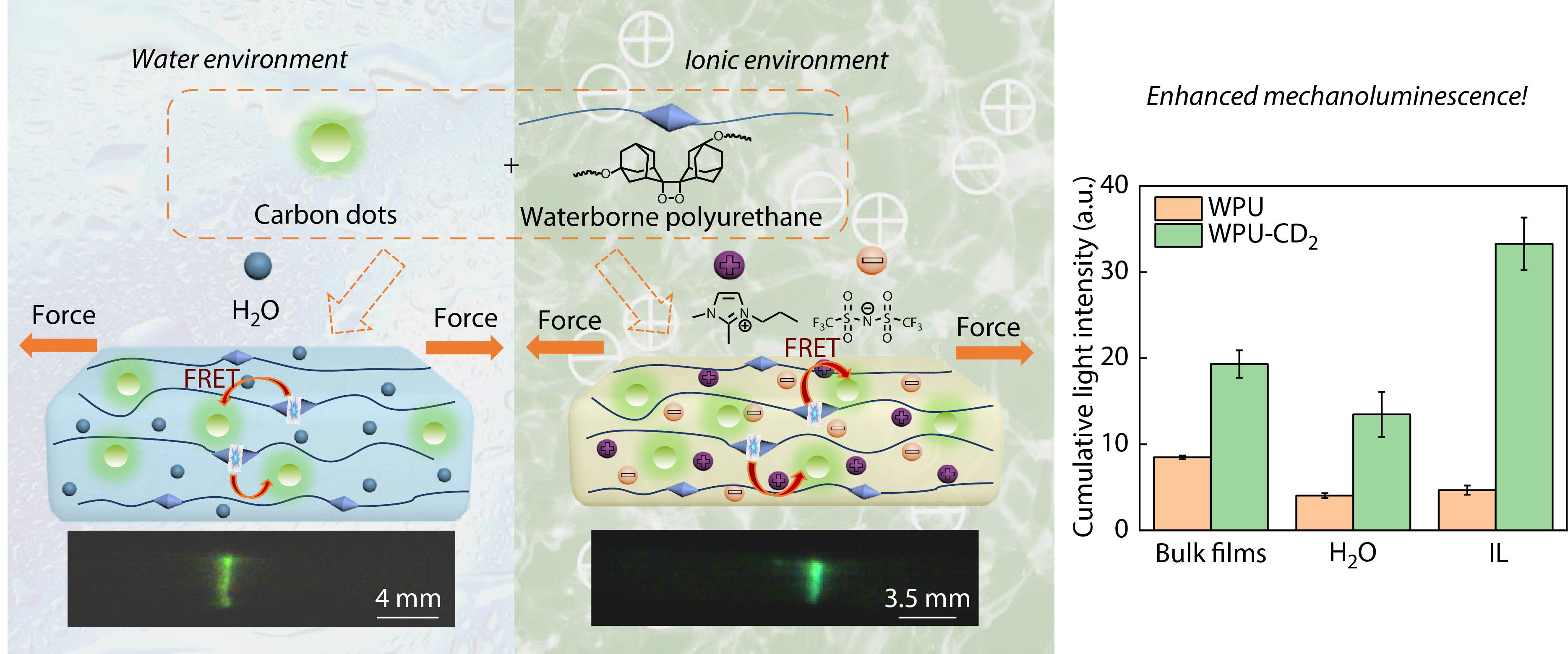

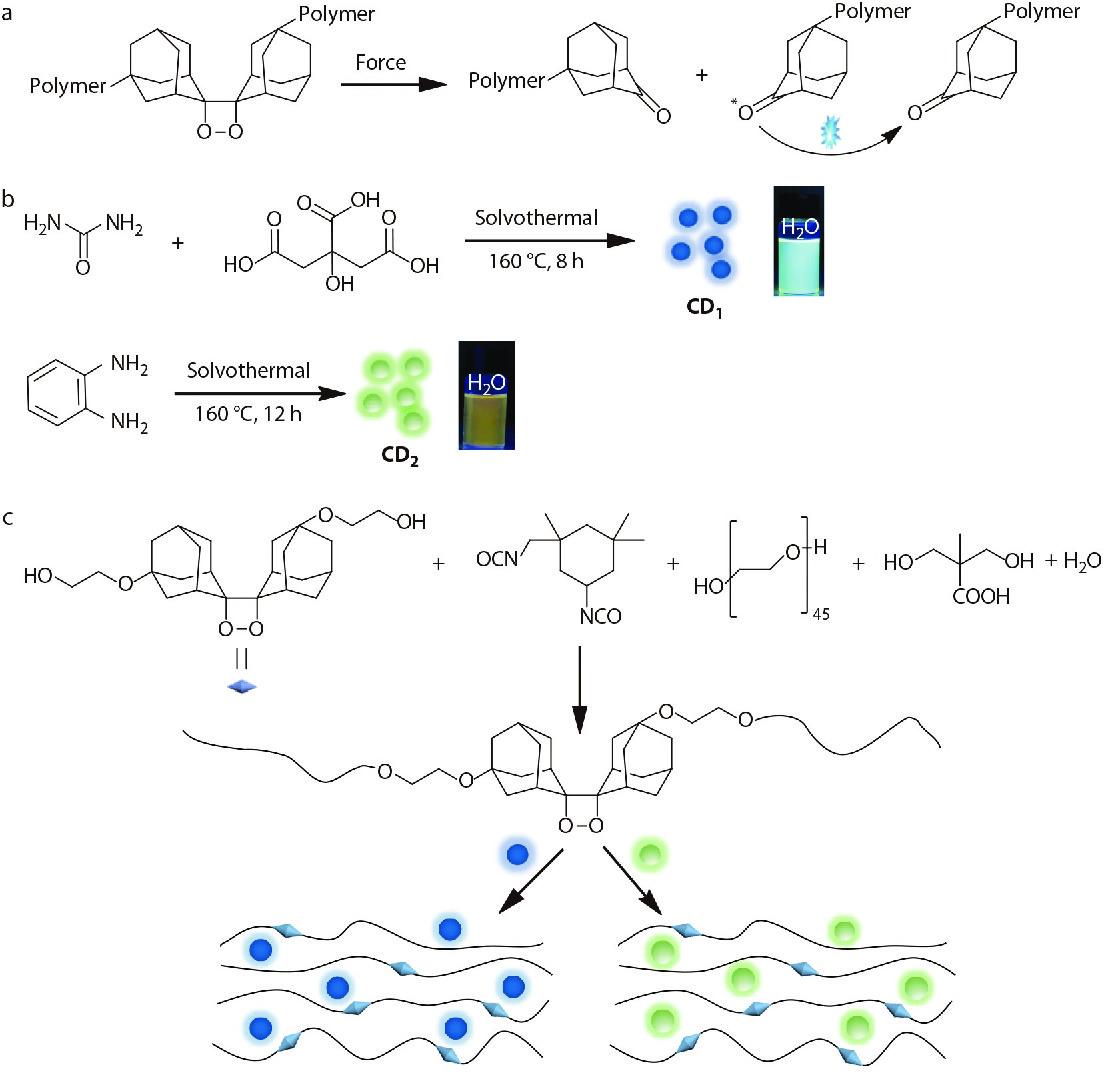

Two kinds of fluorescent carbon dots (CDs) which could be excited at 420 nm were selected and synthesized solvothermally according to literature procedures[32,33] (Scheme 1b). Citric acid and urea were utilized as carbon sources for CD1, and the carbon source of CD2 was o-phenylenediamine. TEM images of CD1 and CD2 showed the average sizes of the nanoparticles were approximately 10 and 21 nm, respectively. Both CD1 and CD2 showed well-resolved lattice spacing (0.21 nm) corresponding to the (100) crystallographic plane of graphitic carbon (Fig. S1 in the electronic supplementary information, ESI). XRD patterns and Raman spectra indicated both disordered amorphous carbon and crystallographic graphitic carbon existed in CDs (Fig. S2 in ESI). FTIR and XPS spectra supported that the surface of the two CDs possessed polar groups (Figs. S3−S5 in ESI),[32,33] which could favor their water compatibility. Photophysical properties of the two CDs in different solvents were characterized by UV-Vis absorption, excitation and FL emission spectra. As demonstrated by Figs. 1(a) and 1(b), in H2O, CD1 and CD2 can be effectively excited by 420 nm light and emit blue-green and yellow fluorescence with maximum at 541 and 578 nm, respectively. The fluorescence quantum yield of aqueous CD1 was much higher than that of CD2. While in ionic liquid (1-propyl-2,3-dimethylimidazolium bis(trifluoromethane sulfonyl)amide, IL), CD2 could absorb more intense light at 420 nm (absorptivity (ε)=6.07 mL·mg−1·cm−1) and emitted much brighter green fluorescence. The enhanced fluorescence quantum yield and the hypsochromic emission wavelength for CD2 were probably due to its ability to form a more stable and uniform dispersion in IL (12.5%, 520 nm, Fig. S6 and Table S1 in ESI).[34] These results implied that both CD1 and CD2 exhibited absorption at 420 nm and emitted bright luminescence, allowing efficient energy transfer from emissive broken 1,2-dioxetane (λem=420 nm) to the CDs acceptors. Compared to reported acceptors of the excited adamantanone,[11,15] CD1 and CD2 are particularly suitable for water and/or IL compatible matrix.

Scheme 1(c) depicts the synthetic scheme of 1,2-dioxetane containing waterborne polyurethane (WPU-0) and its CDs filled composites (WPU-CDs). Herein, 5,5′/7′-di(2-hydroxyethylenoxy)adamantylideneadamantane-1,2-dioxetane (Ad), poly(ethylene glycol) (PEG, 2000 g/mol), 2,2-bis(hydroxymethyl)propionic acid (DMPA), isophorone diisocyanate (IPDI) and H2O were selected as the monomers. Ad first reacted with an excess of IPDI in anhydrous DMAc, resulting in a diisocyanate functionalized mechanophore. Then, PEG, DMPA and H2O were added for polycondensation to afford WPU-0. 1H-NMR and FTIR characterizations manifested the formation of waterborne polyurethane backbone (Figs. S7 and S8 in ESI). The peak at 3.63 ppm was attributed to ―CH2O―, and the peaks at 2.91−3.05 ppm were attributed to the hydrogen on the methylene attached to the carboxyl group, the region of 0.94−2.07 ppm were attributed to ―CH3 and ―CH2 groups on IPDI. The FTIR spectrum of WPU-0 showed characteristic bands at 3351 (N―H stretch), 2868 (C―H stretch), 1717 (free C=O stretch), and 1636 cm−1 (hydrogen-bonded C=O stretch). No peaks assigned to ―NCO groups (2260 cm−1) were observed, which indicated all free ―NCO groups were consumed completely and transformed to urea linkages in the backbone of WPU-0. The WPU-CDs composite films were prepared by mixing different contents of CDs into the WPU-0 matrix via the physically mixing and solvent evaporation prodecures (Table S2 in ESI).

According to DSC and DMA analysis (Figs. S9 and S10), all the films are elastic with a low glass transition temperature (Tg<−30 °C), which would be favorable for efficient mechanotransduction through polymer main chains. SEM characterization of the fracture surfaces of the WPU-CDs films illustrated that no obvious particle aggregation was observed (Fig. S11 in ESI). Besides, most films display good transparency (Fig. S12 in ESI), but at high CD content (e.g., WPU-CD2-2.4%), the film transmittance decreased greatly (Fig. S13 in ESI). Benefiting from the good dispersity of CDs in WPU matrix, their fluorescent feature remained well in these composite films. According to the excitation and emission spectra of these WPU-CDs films (Figs. 1c and 1d), they could emit bright green (λem=510 nm for WPU-CD1, and λem=527 nm for WPU-CD2) luminescence under 420 nm light excitation.

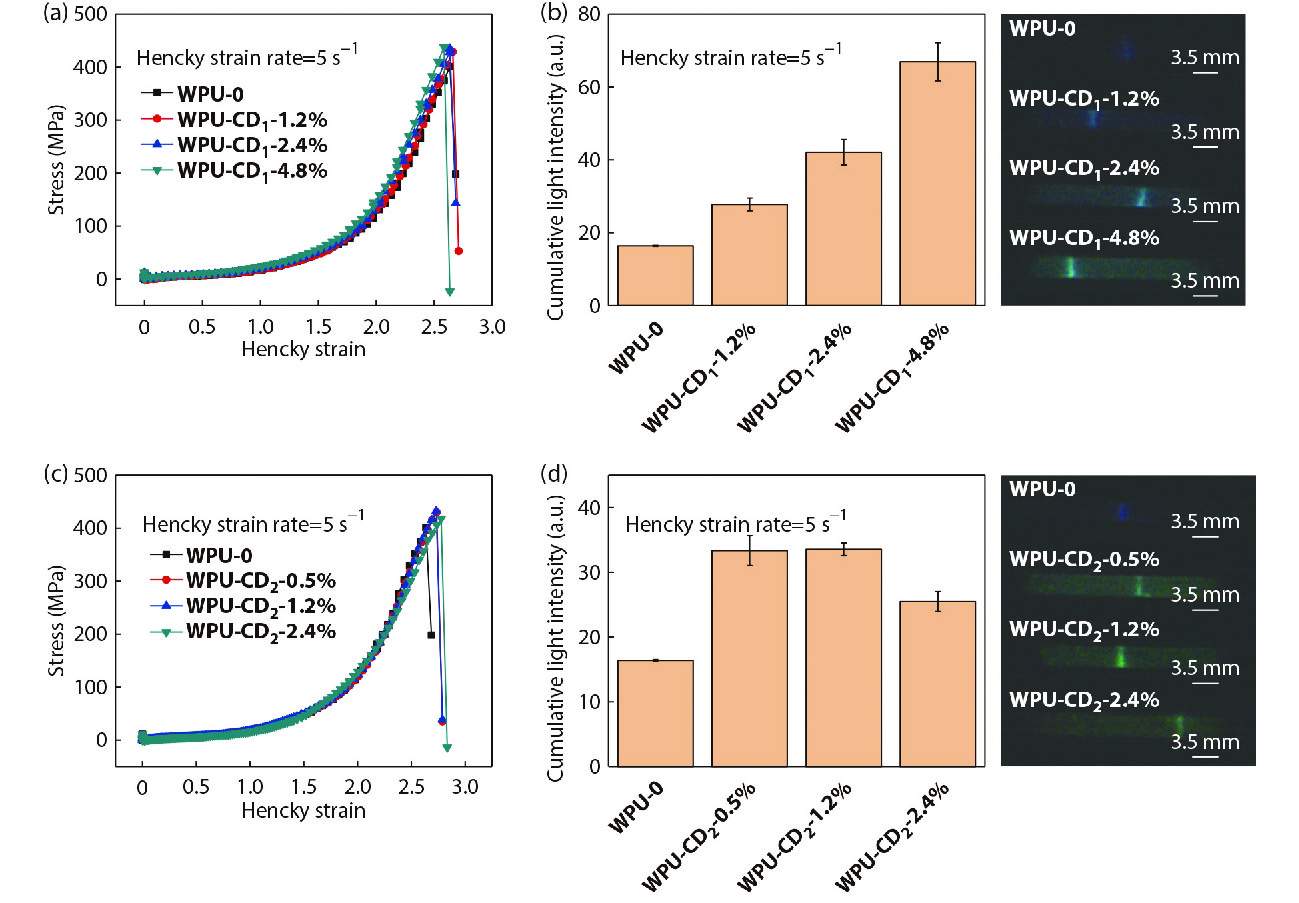

Optomechanical tests of WPU-0 and WPU-CDs films were carried out on a rheometer equipped with two rotating drums that allowed for uniform extensional deformation, and a pco.edge 5.5 camera for in situ video recording in darkness. As illustrated in representative videos (Videos S1−S5 in ESI), upon deformation, the increased chemiluminescence intensity followed with a pronounced and localized emission at the fracture was observed, which could be ascribed to the activation of 1,2-dioxetane groups. Under the same conditions, control samples without covalently linked 1,2-dioxetane could not emit detectable light, confirming the mechanochemical nature of the luminescence. Then, the influence of CD1 or CD2 content on light intensity was studied in detail. Films with different contents of CD1 (0 wt%−4.8 wt%) and CD2 (0 wt%−2.4 wt%) were tested at a Hencky strain rate of 5 s−1. As shown in Figs. 2(a) and 2(c), the stress-Hencky strain curves of WPU-0, WPU-CD1, and WPU-CD2 films were almost identical, indicating that the introduction of CDs into WPU-0 matrix did not influence the mechanical properties of the polymer films. However, the two kinds of CDs with varied contents imposed more significant influence on mechanochemiluminescent properties in the aspects of light color and intensity. As summarized in Figs. 2(b) and 2(d), from WPU-0 to the two kinds of composite films, the mechanochemiluminescent colors changed gradually from blue to the more appreciable green due to energy transfer occurring from blue emission of broken 1,2-dioxetane to green emission of CDs. Moreover, the cumulative light intensity increased almost linearly with the increase of CD1 content. These observations were in line with the energy transfer process from broken 1,2-dioxetanes to the fluorescent CDs.[15,23] From fractured WPU-0 to WPU-CD1-4.8%, the cumulative light intensity was estimated to increase by ca. 4 times. In contrast, the enhancement was not so efficient for WPU-CD2 films, which might be ascribed to the relatively low quantum yield of CD2 (2.8% for CD2 versus 14.4% for CD1 in H2O) and its deep colored composite films. In particular for WPU-CD2-2.4%, its decreased cumulative intensity was mostly due to the low transmittance of the film. (Fig. S13 and Table S1 in ESI).

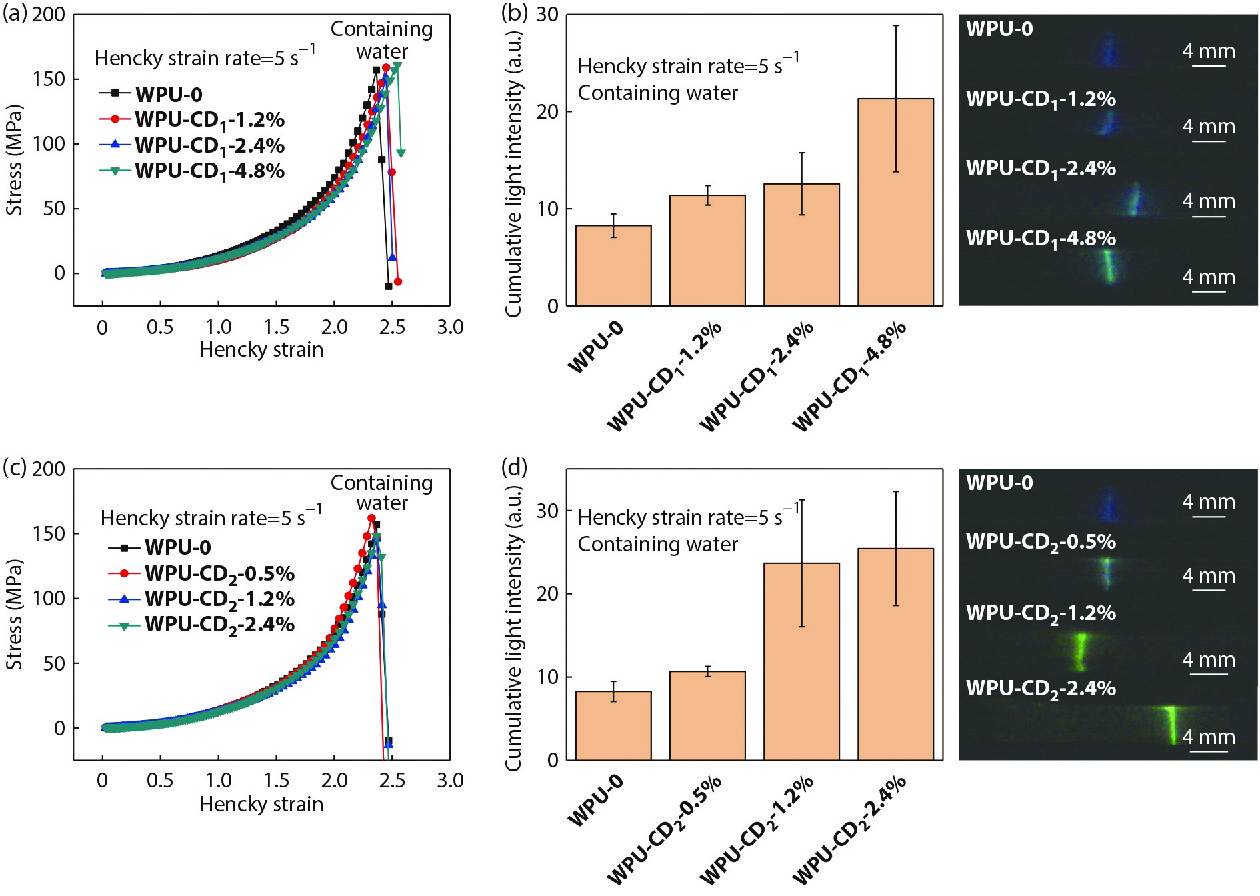

One advantage of WPUs is their good compatibility with water and IL. Besides, in many circumstances, they are used in their wetting states with water or IL retained in polymer networks.[2,4] Therefore, studies on optomechanical properties of the swollen WPU films will be practically helpful to unravel their mechanical integrity and resistance to failure.[8,35,36] As shown in Fig. S14 (in ESI), WPU-0 films could absorb water quickly (water content reached more than 200% in 10 min) and the swollen films were transparent. Water containing WPU-0 and WPU-CDs films with controlled water content around 80% were prepared for optomechanical tests (in ESI). As shown in Figs. 3(a) and 3(c), the fracture stresses of all the swollen films were similar (145−160 MPa). Because of the mechanoluminescence enhancement effect from CDs, all the swollen films could emit blue-green light under tensile tests, despite of the presence of large amount of water in the matrix. Moreover, consistent with the results in their dry state, the cumulative light intensities of swollen WPU-CD1 and WPU-CD2 also increased with the CD contents increasing (Figs. 3b and 3d). These observations manifested that the carbon dots were excellent energy transfer acceptors for mechanochemiluminescent waterborne polymers used in water environment.

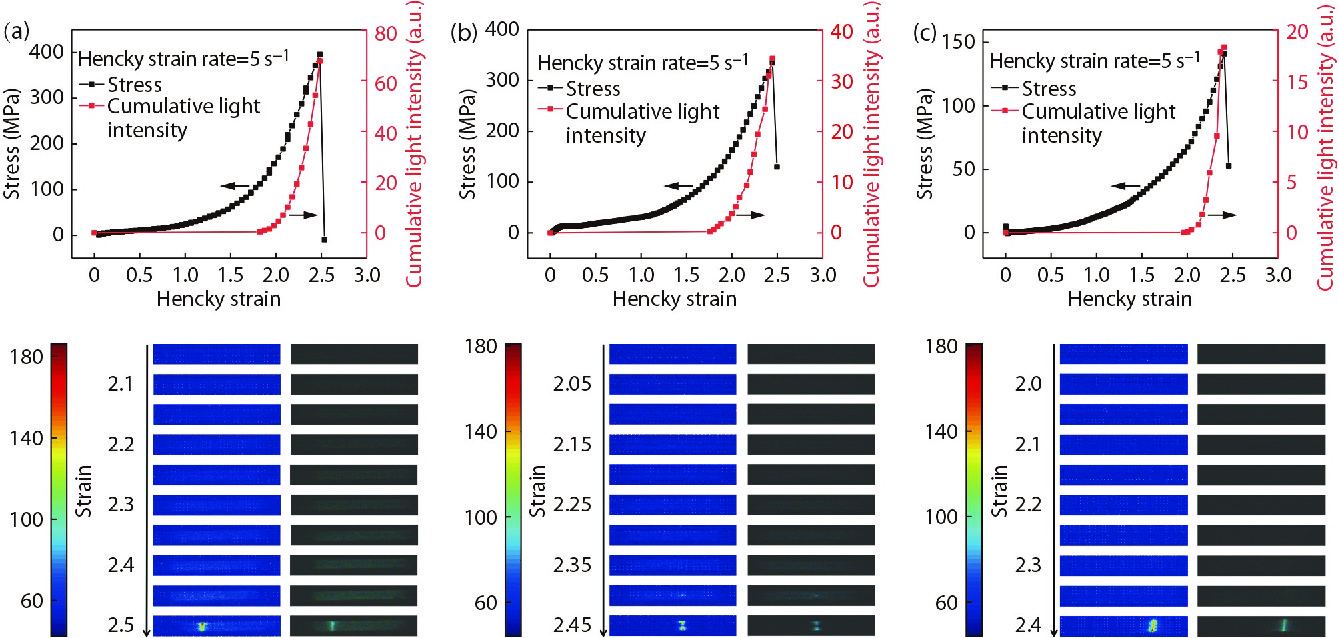

Next, temporal and spatial resolution of mechanochemiluminescence from these elastic films were evaluated. Taking WPU-CD1-4.8% for example, Fig. 4 and Videos S1−S3 (in ESI) demonstrated the capability of 1,2-dioxetane in monitoring the evolution of stress and light from the deformed films in their different states (dried, defected and swollen states). Useful information deduced from image analysis is as follows: (1) the luminescence signal was detected only at high Hencky strain, corresponding to good temporal resolution of mechanochemiluminescence with the covalent bond scission mainly occurring near fracture; (2) mapping of mechanochemiluminescence during the fracture of the pre-defected film illustrated the “concentrated” covalent bond scission started around the small and weak spot, demonstrating good spatial resolution of mechanochemiluminescence for self-reporting of defects; (3) the fraction of light intensity of the fracture frame relative to total light intensity is about 19% for WPU-CD1-4.8% dried film and 47% for its water containing film, suggesting that the swollen film exhibited more transient emission just prior to fracture. This might be due to the H-bonding interactions between water and polymer matrix, leading to a crosslinked network for efficient force transduction and mechanoactivation.[4] Similar results were found for WPU-CD2-1.2% films (Fig. S15 in ESI).

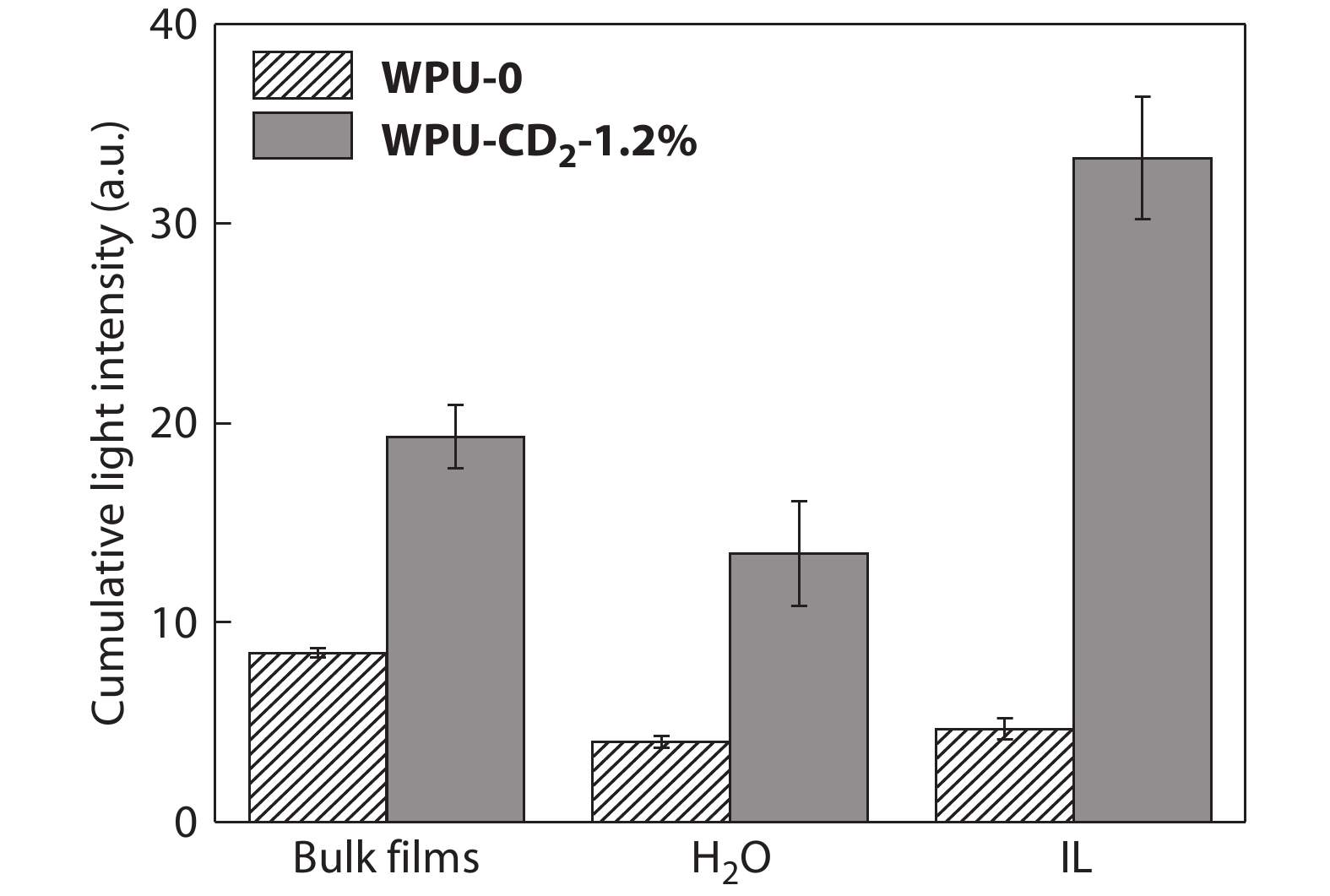

Besides the water absorption, WPU-0 and WPU-CDs could also swell in ionic liquid, resulting in elastic mechanochemiluminescent films with electric conductive properties. As shown in Table S3 and Fig. S16 (in ESI), the conductivity and mechanical property of the swollen films can be adjusted with the addition of different amounts of IL. As the IL content increased, the conductivity of the films increased, meanwhile, their fracture stress decreased and the extensibility enhanced. Concerning the excellent fluorescent property of CD2 in IL, mechanochemiluminescent properties of IL swollen WPU-CD2 films were investigated in detail. Compared to their water swollen counterparts, more significant enhancement effect of CD2 on mechanochemiluminescence from IL-based film was verified. As summarized in Fig. 5, all the films without the addition of CD2 could only emit weak light and the quenching effect was especially prominent for the water and IL containing films. In contrast, the light intensity of IL swollen WPU-CD2-1.2% film was up to 7 times higher than that of WPU-0-IL, which on the other hand, was a more than twofold increase from that of WPU-CD2-1.2%-H2O. Furthermore, with this greatly improved mechanochemiluminescent performance, the localization of bond scission in space and time from the broken WPU-CD2-1.2%-IL film was realized. For instance, Fig. S18 and Videos S4 and S5 (in ESI) showed that the evolution of macroscopic failure initiated form a small defect in a WPU-CD2-1.2%-IL film could be distinguished by this mechanochemiluminescent strategy. Collectively, all these results highlighted the capability of chemiluminescent 1,2-dioxetane and CDs, when joined together in wetting WPU films (water or IL-based networks), in sensitively visualizing stress distribution and bond scission during fracture.

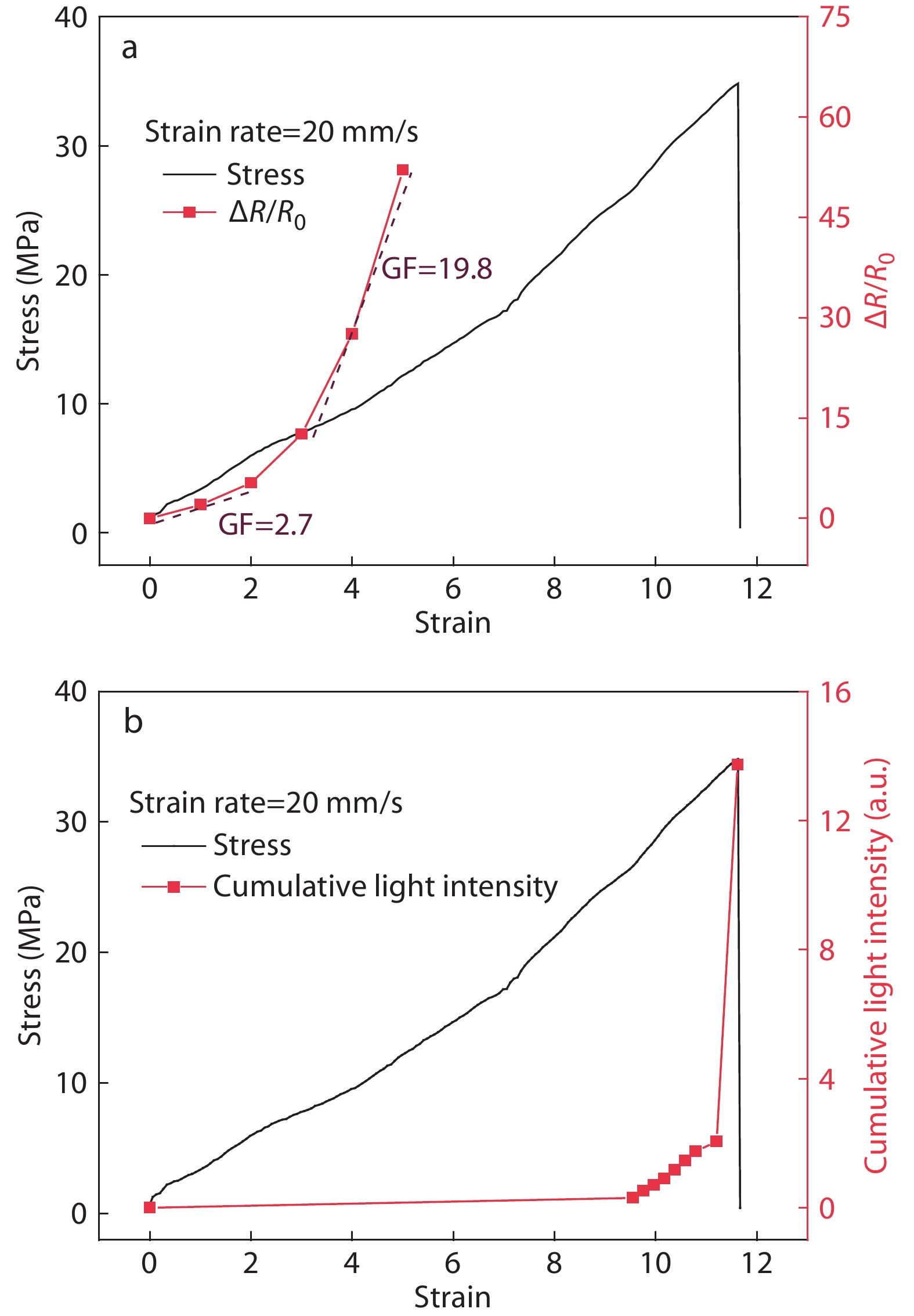

Alongside with the increased light intensity, with IL full-filled in the WPU matrix, the conductive swollen films also exhibited increased resistance change (ΔR/R0) when stretched. Therefore, this kind of films is expected to be served as a multi-mode strain sensor. Taking the WPU-CD2-1.2%-IL film for illustration (Fig. 6), the gauge factor (GF), which is the slope of the (ΔR/R0) versus strain plot and an important parameter for evaluating the sensitivity of the strain sensor, was estimated. The mathematical fit of the (ΔR/R0) versus strain plot generates two different slopes of 2.7 and 19.8, which represent the GF of the strain sensor at low strain of 0%−200% and large strain of 300%−500%, respectively. Meanwhile, the mechanochemiluminescent signal was record and the evolution of stress and cumulative light intensity versus strain was investigated, showing strain sensing in a luminescent way only working at high strain (>900%). In this way, both electrical and optical signals can be employed for strain sensing. Notably, due to the different sensitivities of the elicited two types of signals, they are versatile in different responsive ranges. Overall, the combination of electrical and optical strain sensing not only offers a new type of multi-mode strain sensors, but also expands the detection range of strain greatly.

CONCLUSIONS

In summary, we have successfully prepared a series of mechanochemiluminescent waterborne polyurethane based composite films (WPU-CDs) that comprised 1,2-dioxetane in the polymer main chain and fluorescent carbon dots filled in the matrix. The carbon dots were proved as effective energy acceptors of broken 1,2-dioxetane to improve the mechanochemiluminescent intensity from deformed bulk and swollen films, thus, promoting the stress reporting capability of 1,2-dioxetane applicable in different environments. For the first time, intense mechanochemiluminescence from swollen films with large amount of polar solvents (water and IL) was realized, which allowed for monitoring and mapping the force-induced covalent bond scission events in wetting states with high spatial and temporal resolution. Moreover, with ionic liquid contributing to the conductive properties of the films, a new kind of strain sensors, featuring with both electrical and luminescent signals responsive at a broad range of strain, was fabricated. Our work thus not only extends the applications of carbon dots, but also offers a feasible strategy to fabricate mechanochemiluminescent waterborne polymers which will be valuable as sensitive force/strain sensing materials applicable in various states.

Waterborne polyurethanes: a review

J. Disper. Sci. Technol. 2018 39 507 516Honarkar, H. Waterborne polyurethanes: a review. J. Disper. Sci. Technol. 2018, 39, 507−516.

Synthesis, properties, and applications of ion-containing polyurethane segmented copolymers

Macromol. Chem. Phys. 2014 215 2161 2174Nelson, A. M.; Long, T. E. Synthesis, properties, and applications of ion-containing polyurethane segmented copolymers. Macromol. Chem. Phys. 2014, 215, 2161−2174.

Preparation and characterization of controlled heparin release waterborne polyurethane coating systems

Chinese J. Polym. Sci. 2016 34 679 687Song, Y.; Gao, Y.; Pan, Z.; Zhang, Y.; Li, J.; Wang, K.; Li, J.; Tan, H.; Fu, Q. Preparation and characterization of controlled heparin release waterborne polyurethane coating systems. Chinese J. Polym. Sci. 2016, 34, 679−687.

Ultrastrong and tough supramolecular hydrogels from multiurea linkage segmented copolymers with tractable processablity and recyclability

Macromol. Rapid Commun. 2017 38 1700275Yang, N.; Yang, H.; Shao, Z.; Guo, M. Ultrastrong and tough supramolecular hydrogels from multiurea linkage segmented copolymers with tractable processablity and recyclability. Macromol. Rapid Commun. 2017, 38, 1700275.

Ionic skin

Adv. Mater. 2014 26 7608 7614Sun, J.; Keplinger, C.; Whitesides, G. M.; Suo, Z. Ionic skin. Adv. Mater. 2014, 26, 7608−7614.

Mechanically robust, elastic, and healable ionogels for highly sensitive ultra-durable ionic skins

Adv. Mater. 2020 32 2002706Li, T.; Wang, Y.; Li, S.; Liu, X.; Sun, J. Mechanically robust, elastic, and healable ionogels for highly sensitive ultra-durable ionic skins. Adv. Mater. 2020, 32, 2002706.

Elastic conducting polymer composites in thermoelectric modules

Nat. Commun. 2020 11 1424 1433Kim, N.; Lienemann, S.; Petsagkourakis, I.; Mengistie, D. A.; Kee, S.; Ederth, T.; Gueskine, V.; Leclere, P.; Lazzaroni, R.; Crispin, X.; Tybrandt, K. Elastic conducting polymer composites in thermoelectric modules. Nat. Commun. 2020, 11, 1424−1433.

Mechanochemical tools for polymer materials

Chem. Soc. Rev. 2021 50 4100 4140Chen, Y.; Mellot, G.; van Luijk, D.; Creton, C.; Sijbesma, R. P. Mechanochemical tools for polymer materials. Chem. Soc. Rev. 2021, 50, 4100−4140.

Force-induced activation of covalent bonds in mechanoresponsive polymeric materials

Nature 2009 459 68 72Davis, D. A.; Hamilton, A.; Yang, J.; Cremar, L. D.; Van Gough, D.; Potisek, S. L.; Ong, M. T.; Braun, P. V.; Martínez, T. J.; White, S. R.; Moore, J. S.; Sottos, N. R. Force-induced activation of covalent bonds in mechanoresponsive polymeric materials. Nature 2009, 459, 68−72.

Rhodamine mechanophore functionalized mechanochromic double network hydrogels with high sensitivity to stress

Chinese J. Polym. Sci. 2020 38 24 36Wang, L.; Yang, K.; Zhou, Q.; Yang, H.; He, J.; Zhang, X. Rhodamine mechanophore functionalized mechanochromic double network hydrogels with high sensitivity to stress. Chinese J. Polym. Sci. 2020, 38, 24−36.

Mechanically induced chemiluminescence from polymers incorporating a 1,2-dioxetane unit in the main chain

Nat. Chem. 2012 4 559 562Chen, Y.; Spiering, A. J. H.; Karthikeyan, S.; Peters, G. W. M.; Meijer, E. W.; Sijbesma, R. P. Mechanically induced chemiluminescence from polymers incorporating a 1,2-dioxetane unit in the main chain. Nat. Chem. 2012, 4, 559−562.

Dioxetanes as mechanoluminescent probes in thermoplastic elastomers

Macromolecules 2014 47 3797 3805Chen, Y.; Sijbesma, R. P. Dioxetanes as mechanoluminescent probes in thermoplastic elastomers. Macromolecules 2014, 47, 3797−3805.

An optomechanical study of mechanoluminescent elastomeric polyurethanes with different hard segments

Polym. Chem. 2020 11 1877 1884Liu, S.; Yuan, Y.; Li, J.; Sun, S.; Chen, Y. An optomechanical study of mechanoluminescent elastomeric polyurethanes with different hard segments. Polym. Chem. 2020, 11, 1877−1884.

Phase-locked dynamic and mechanoresponsive bonds design toward robust and mechanoluminescent self-healing polyurethanes: a microscopic view of self-healing behaviors

Macromolecules 2019 52 9376 9382Yan, C.; Yang, F.; Wu, M.; Yuan, Y.; Chen, F.; Chen, Y. Phase-locked dynamic and mechanoresponsive bonds design toward robust and mechanoluminescent self-healing polyurethanes: a microscopic view of self-healing behaviors. Macromolecules 2019, 52, 9376−9382.

Improving mechanoluminescent sensitivity of 1,2-dioxetane-containing thermoplastic polyurethanes by controlling energy transfer across polymer chains

Macromolecules 2018 51 9019 9025Yuan, W.; Yuan, Y.; Yang, F.; Wu, M.; Chen, Y. Improving mechanoluminescent sensitivity of 1,2-dioxetane-containing thermoplastic polyurethanes by controlling energy transfer across polymer chains. Macromolecules 2018, 51, 9019−9025.

Covalently cross-linked and mechanochemiluminescent polyolefins capable of self-healing and self-reporting

CCS Chem. 2020 2 1316 1324Deng, Y.; Yuan, Y.; Chen, Y. Covalently cross-linked and mechanochemiluminescent polyolefins capable of self-healing and self-reporting. CCS Chem. 2020, 2, 1316−1324.

Toughening elastomers with sacrificial bonds and watching them break

Science 2014 344 186 189Ducrot, E.; Chen, Y.; Bulters, M.; Sijbesma, R. P.; Creton, C. Toughening elastomers with sacrificial bonds and watching them break. Science 2014, 344, 186−189.

Mechanics of elastomeric molecular composites

Proc. Natl. Acad. Sci. U.S.A. 2018 115 9110 9115Millereau, P.; Ducrot, E.; Clough, J. M.; Wiseman, M. E.; Brown, H. R.; Sijbesma, R. P.; Creton, C. Mechanics of elastomeric molecular composites. Proc. Natl. Acad. Sci. U.S.A. 2018, 115, 9110−9115.

Visualized bond scission in mechanochemiluminescent polymethyl acrylate/cellulose nanocrystals composites

ACS Macro Lett. 2020 9 438 442Chen, W.; Yuan, Y.; Chen, Y. Visualized bond scission in mechanochemiluminescent polymethyl acrylate/cellulose nanocrystals composites. ACS Macro Lett. 2020, 9, 438−442.

Covalent bond scission in the mullins effect of a filled elastomer: real-time visualization with mechanoluminescence

Adv. Funct. Mater. 2016 26 9063 9074Clough, J. M.; Creton, C.; Craig, S. L.; Sijbesma, R. P. Covalent bond scission in the mullins effect of a filled elastomer: real-time visualization with mechanoluminescence. Adv. Funct. Mater. 2016, 26, 9063−9074.

Enhanced optomechanical properties of mechanochemiluminescent poly(methyl acrylate) composites with granulated fluorescent conjugated microporous polymer fillers

Chem. Sci. 2019 10 2206 2211Yuan, Y.; Chen, W.; Ma, Z.; Deng, Y.; Chen, Y.; Chen, Y.; Hu, W. Enhanced optomechanical properties of mechanochemiluminescent poly(methyl acrylate) composites with granulated fluorescent conjugated microporous polymer fillers. Chem. Sci. 2019, 10, 2206−2211.

Advanced chemistry of dioxetane-based chemiluminescent substrates originating from bioluminescence

J. Photochem. Photobiol. C 2004 5 27 53Matsumoto, M. Advanced chemistry of dioxetane-based chemiluminescent substrates originating from bioluminescence. J. Photochem. Photobiol. C 2004, 5, 27−53.

Sensitized mechanoluminescence design toward mechanically induced intense red emission from transparent polymer films

Macromolecules 2020 53 905 912Yang, F.; Yuan, Y.; Sijbesma, R. P.; Chen, Y. Sensitized mechanoluminescence design toward mechanically induced intense red emission from transparent polymer films. Macromolecules 2020, 53, 905−912.

The fluorescence mechanismof carbon dots, and methods for tuning their emission color: a review

Microchim. Acta 2019 186 583Yan, F.; Sun, Z.; Zhang, H.; Sun, X.; Jiang, Y.; Bai, Z. The fluorescence mechanismof carbon dots, and methods for tuning their emission color: a review. Microchim. Acta 2019, 186, 583.

Luminescent carbon nanodots: emergent nanolights

Angew. Chem. Int. Ed. 2010 49 6726 6744Baker, S. N.; Baker, G. A. Luminescent carbon nanodots: emergent nanolights. Angew. Chem. Int. Ed. 2010, 49, 6726−6744.

The rapid and large-scale production of carbon quantum dots and their integration with polymers

Angew. Chem. Int. Ed. 2021 60 8585 8595Du, X.; Wang, C.; Wu, G.; Chen, S. The rapid and large-scale production of carbon quantum dots and their integration with polymers. Angew. Chem. Int. Ed. 2021, 60, 8585−8595.

Carbon quantum dots and their applications

Chem. Soc. Rev. 2015 44 362 381Lim, S. Y.; Shen, W.; Gao, Z. Carbon quantum dots and their applications. Chem. Soc. Rev. 2015, 44, 362−381.

Carbon dots: a new type of carbon-based nanomaterial with wide applications

ACS Cent. Sci. 2020 6 2179 2195Liu, J.; Li, R.; Yang, B. Carbon dots: a new type of carbon-based nanomaterial with wide applications. ACS Cent. Sci. 2020, 6, 2179−2195.

Carbon dots: synthesis, formation mechanism, fluorescence origin and sensing applications

Green Chem. 2019 21 449 471Liu, M.; Chen, B.; Li, C.; Huang, C. Carbon dots: synthesis, formation mechanism, fluorescence origin and sensing applications. Green Chem. 2019, 21, 449−471.

Waterborne polyurethane/carbon quantum dot nanocomposite as a surface coating material exhibiting outstanding luminescent performance

Prog. Org. Coat. 2020 138 105433Qiang, T.; Han, M.; Wang, X. Waterborne polyurethane/carbon quantum dot nanocomposite as a surface coating material exhibiting outstanding luminescent performance. Prog. Org. Coat. 2020, 138, 105433.

LCST-type liquid-liquid phase separation behaviour of poly(ethylene oxide) derivatives in an ionic liquid

Chem. Commun. 2008 4939 4941Tsuda, R.; Kodama, K.; Ueki, T.; Kokubo, H.; Imabayashi, S.; Watanabe, M. LCST-type liquid-liquid phase separation behaviour of poly(ethylene oxide) derivatives in an ionic liquid. Chem. Commun. 2008, 4939−4941.

Red, green, and blue luminescence by carbon dots: full-color emission tuning and multicolor cellular imaging

Angew. Chem. Int. Ed. 2015 54 5360 5363Jiang, K.; Sun, S.; Zhang, L.; Lu, Y.; Wu, A.; Cai, C.; Lin, H. Red, green, and blue luminescence by carbon dots: full-color emission tuning and multicolor cellular imaging. Angew. Chem. Int. Ed. 2015, 54, 5360−5363.

Bright and multicolor chemiluminescent carbon nanodots for advanced information encryption

Adv. Sci. 2019 6 1802331Shen, C.; Lou, Q.; Lv, C.; Zang, J.; Qu, S.; Dong, L.; Shan, C. Bright and multicolor chemiluminescent carbon nanodots for advanced information encryption. Adv. Sci. 2019, 6, 1802331.

Ionic liquid mediated carbon dots: preparations, properties and applications

Trac-trend Anal. Chem. 2019 119 115638Zheng, A.; Guo, T.; Guan, F.; Chen, X.; Shu, Y.; Wang, J. Ionic liquid mediated carbon dots: preparations, properties and applications. Trac-trend Anal. Chem. 2019, 119, 115638.

Investigation on viscoelasticity of waterborne polyurethane with azobenzene-containing pendant groups under ultraviolet and visible-light irradiation

Chinese J. Polym. Sci. 2019 37 1267 1272Liu, Y.; Liu, D.; Li, S.; Liang, H.; Zhu, F. Investigation on viscoelasticity of waterborne polyurethane with azobenzene-containing pendant groups under ultraviolet and visible-light irradiation. Chinese J. Polym. Sci. 2019, 37, 1267−1272.

Light and force dual-responsive waterborne polyurethane in multiple states

RSC Adv. 2017 7 12682 12689Zhang, Q.; Wang, Y.; Xing, C.; Cai, Y.; Xi, K.; Jia, X. Light and force dual-responsive waterborne polyurethane in multiple states. RSC Adv. 2017, 7, 12682−12689.